Reduce Risk To Food & Beverage With Our Validation Tools

We 3D print standard check weight and validation tools to NIST Standards, and have developed a new method of testing utilizing our Manufacturing Test Block for metal detectors and check weighing systems. Scroll down for additional Info.

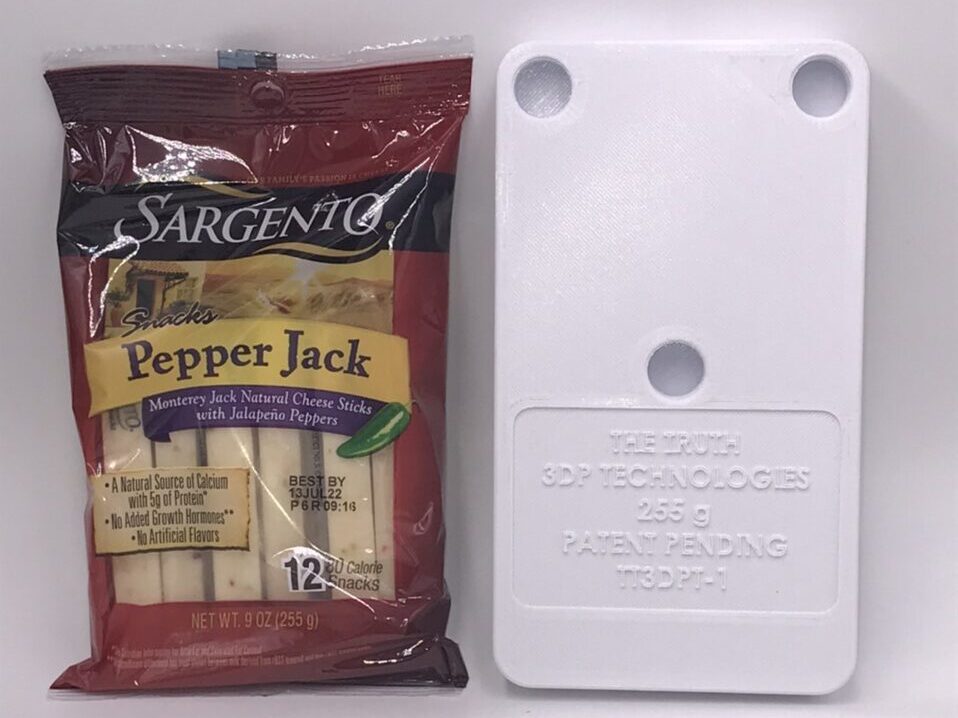

Our Custom 3d Printed Test Block* Streamlines Validation & Reduces Risk

The manufacturing test block is customizable in shape & weight to customer needs and has pre-made holes in multiple locations on the test block. A metal detector plug that has a contaminant within the plug that can be sensed by a detector and can be screwed in each pre-made hole to test for contaminants. The test block can be placed on a conveyor system to test for contaminants within the conveyor line full of packaged products, while not interrupting the other packages. *US Patent # 12,196,732 B2

a new method of testing for Metal Detectors and Check Weighing Systems

Our Patented custom 3D-printed Test Block will revolutionize the method of testing in food manufacturing for metal detection and check weighing validation processes.

The test block mimics the dimension and weight of your product to +/- .05 grams. All of our custom test weights are certified to NIST traceable standards.

The test block is multi-purpose and can be used for metal detection and check weighing based on your equipment specifications within your facility.

Validate without stopping production

Since we 3D print the test block to mimic your product dimensions and weight, just place the Test Block on the production line at a safe area (No Pinch Points) and let it ride the conveyor to the metal detector or check weigher.

Reduce contamination Risk to Food Safety

The Test Block has been determined by the Patent Examiner to be used as a Method of Testing & Method of Calibration.

Safer & more effective detection

Just place the Test Weight on the production line at a safe area – What’s a Safe Area? Determine an area with no pinch points or hazards when the employee places the test block on the line.

Additional Value Added features

Reject timing & Calibration

Use as a visual aid for product reject timing to reduce the risk of a foreign material or product contamination.

Reduces Product Damage

Precise detection of metal detection with proper kick-off timing reduces wasted product or damage.

Reduces Packaging Waste

Less wasted products means less wasted packaging.

External Food Audits

Can be used as a tool to assist in passing external food safety audits for metal detectors & check weighers.

Standard Validation Tools

Check weights & Validation Tools

Also available in custom weights, shapes and sizes.

We bring the custom insoles directly to your workforce.

Custom-fit 3D printed support that helps reduce fatigue, prevents injury, and keeps your team performing at their best at work, and beyond.